Optical fiber sensing technology for smart structures

The deterioration and damage of civil infrastructure due to aging and earthquakes pose a significant threat to society. One promising solution for monitoring the condition of structures is through the use of optical fiber sensing. By embedding long optical fibers into structures, strain and temperature distributions along the fibers can be detected, functioning as “artificial nerves” that allow the structures to “speak up” when experiencing stress or overheating. These “smart structures,” equipped with enhanced maintenance capabilities, hold great potential for improving efficiency.

Our group is focused on the development of optical fiber sensing technology for implementing smart structures, with a particular focus on three areas: 1) distributed optical fiber sensing, 2) polymer optical fiber sensing, and 3) the application of the plastic fiber fuse effect. In this page, we provide a brief overview of these topics.

We are also proud to announce the recent development of a new type of LiDAR. For more information, please see the press release (in Japanese).

Distributed optical fiber sensors

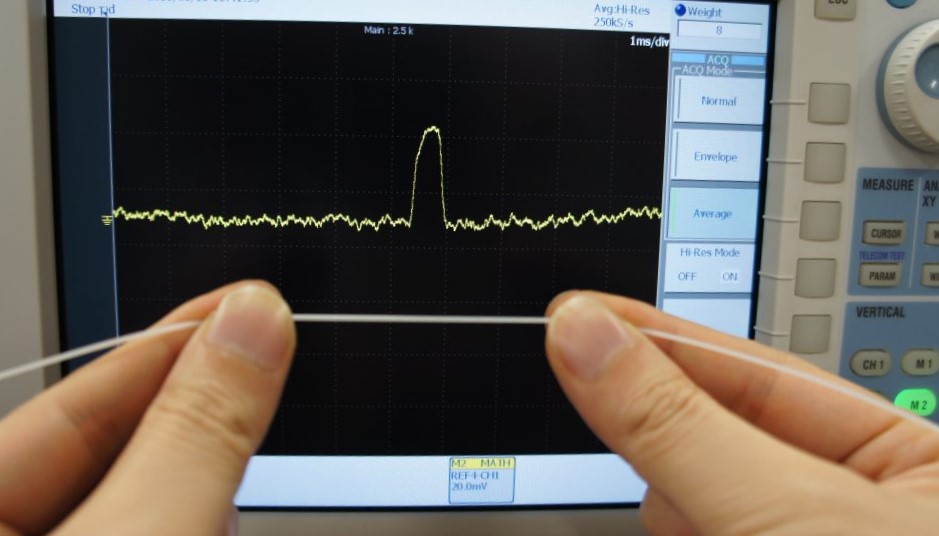

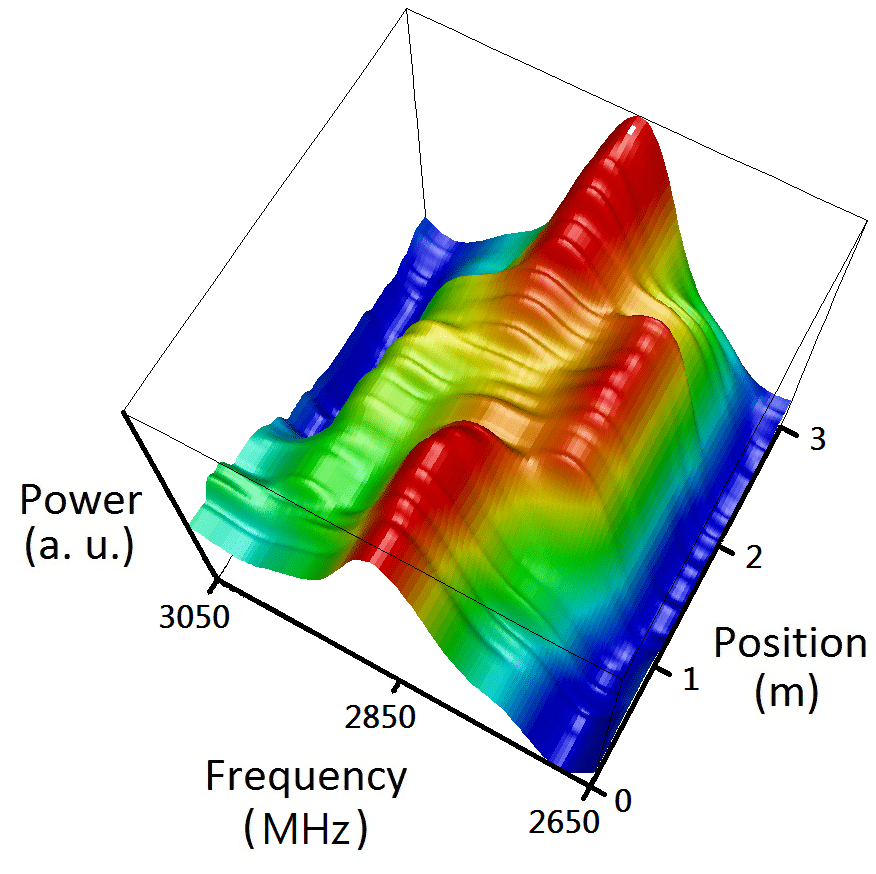

Optical fiber sensors that can measure strain, temperature, etc. at arbitrary positions along optical fibers are called “distributed optical fiber sensors.” Our distributed optical fiber sensors are based on optical frequency shift caused by Brillouin scattering. We are focused on an original distributed sensing technique called “Brillouin optical correlation-domain reflectometry (BOCDR).” This technique was invented by Assoc. Prof. Mizuno in 2008 (under the supervision of Prof. Hotate, who was a professor at the University of Tokyo and is currently the President at Toyota Technological Institute). BOCDR is a distributed sensing method that uses light injection at only one end of the sensing fiber to achieve high spatial resolution, random accessibility, and cost efficiency. In recent years, we have even achieved real-time operation with BOCDR (as demonstrated in this movie). However, we still face some challenges in bringing BOCDR into practical use. Our primary goal is to continue advancing distributed fiber-optic sensing technology and achieving world-class performance (including BOCDR).

※ For details, refer to the articles of Ultrasonic Techno and Optics Highlight (in Japanese).

References: Opt. Express 16, 12148 (2008); J. Lightwave Technol. 28, 3300 (2010); Light: Sci. Appl. 5, e16184 (2016); Opt. Express 29, 13794 (2021) .

Plastic (polymer) optical fiber sensors

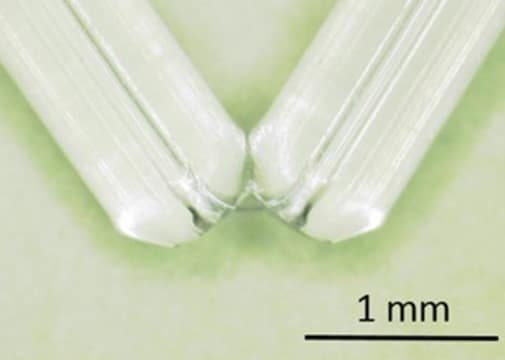

Optical fibers used for sensing have mainly been silica glass optical fibers, which are widely used for telecommunication as well. However, as silica glass fibers break at relatively small strains of several percent, it was difficult to measure larger strains. To tackle this issue, we have been working on fiber-optic sensing using plastic (or polymer) optical fibers (POFs), which are sufficiently flexible to withstand over 100% strain. To date, we have succeeded in observing Brillouin scattering in POFs for the first time and clarified its numerous unique properties such as memory function and Brillouin frequency shift hopping. We have also demonstrated distributed Brillouin sensing along a POF for the first time in the world. In addition, our POF-related work includes fiber Bragg gratings (FBGs), long-period gratings (LPGs), and intermodal interference. Thus, our second mission is to develop novel POF-based sensing technology. We are in collaboration with research groups at Cyprus University of Technology and BAM, Germany.

※ For details, refer to our review paper published in Photonics Research (Open Access).

References: Appl. Phys. Lett. 97, 021103 (2010); J. Lightwave Technol. 32, 3999 (2014); Opt. Lett. 44, 2097 (2019); Appl. Phys. Express 12, 082007 (2019); Photon. Res. 9, 1719 (2021) .

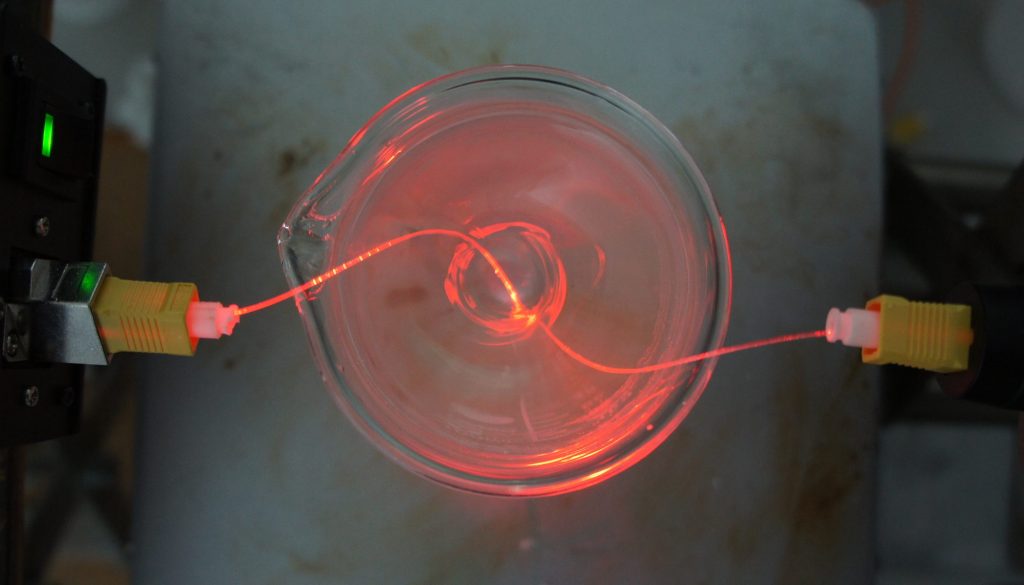

Plastic optical fiber fuse and its applications

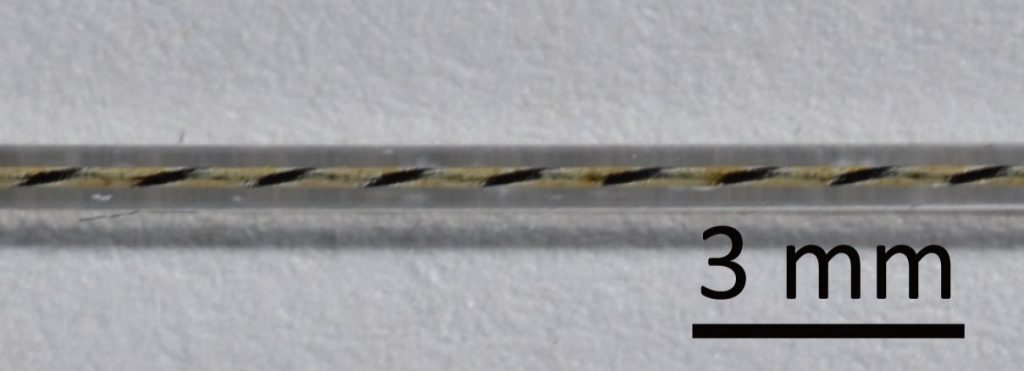

Optical fiber fuse is the continuous self-destruction of a fiber by propagating light. High-power light propagating through the fiber results in local heating and the creation of an optical discharge that is then captured in the fiber core and travels back along the fiber toward the light source, consuming the light energy. Its properties have been well investigated only in glass fibers (see Dr. Todoroki’s website). In 2014, we succeeded in observing the fiber fuse in plastic optical fibers (POFs) for the first time (see this movie). Since then, we have clarified the unique properties of the POF fuse, including its slow propagation velocity (1–2 orders of magnitude slower than that in silica fibers) and low threshold power density (1/180 of the value for silica fibers), etc. We have also shown that an oscillatory carbonized continuous curve is formed after the fuse passage, which exhibits electrical conductivity. These days, fused POFs have attracted considerable attention as novel optical materials, and their engineering applications have been extensively studied. We have recently developed a fused-POF-based high-sensitivity magnetic field sensor in collaboration with Brazilian and Portuguese groups.

※ For details, refer to our review paper published in Advanced Photonics Research (Open Access). The articles of Optical Alliances (in Japanese) and Laser Focus World (in English) are also available.

References: Appl. Phys. Lett. 104, 043302 (2014); Sci. Rep. 4, 4800 (2014); Opt. Express 26, 12939 (2018); Adv. Photon. Res. 2, 2000078 (2021); Adv. Photon. Res. 3, 2100209 (2022).